Description

COMPRESSED AIR FILTERS

Compressed air coalescing filters will significantly improve the air to your plant by removing airborne contaminants leading to reduced maintenance and avoiding product spoilage, meaning increased productivity and reduced business expenses.

Compressed air used in industrial applications can contain more than 100 million polluting particles for every 1.0 Nm³ of compressed air. Depending on the grade of filter used, contaminant particles can be effectively removed and the air deemed technically oil free.

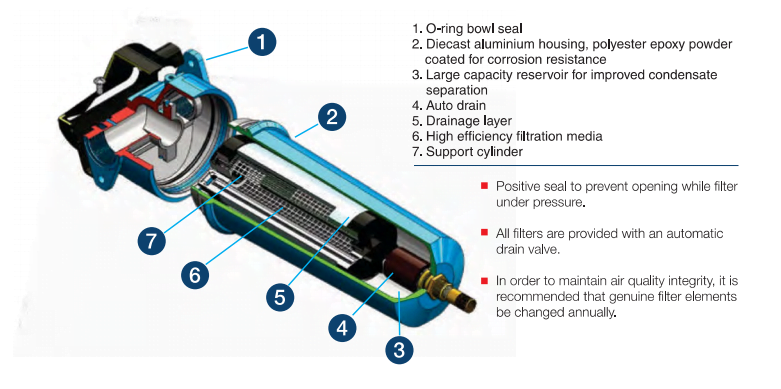

FEATURES

Most of the particles contained in the air stream are so small (less than 5 microns) they cannot be intercepted by the standard intake filters installed in a typical air compressor.

Compressed air will contain minute traces of oil aerosols and oil vapour which become entrained in the airstream. These oil particles can cause damage to system components as well as product spoilage. Fitting the appropriate compressed air coalescing and absorption filters to meet the quality needs of your system can remove these particles.

It is not only oil lubricated compressors that require filtering, “oil free” compressors still draw in oil and oil vapours from the atmosphere.

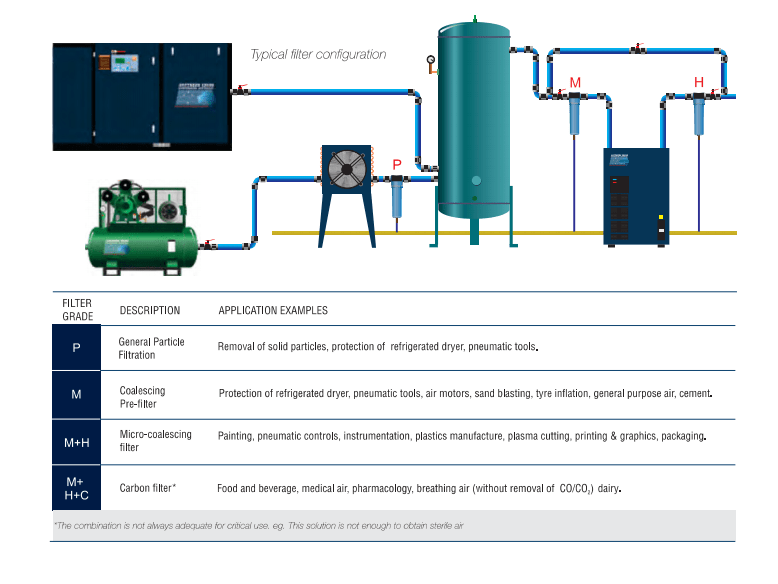

There are 4 main types of compressed air filters, the optimal set up for your compressed air system will depend on the application.

Reviews

There are no reviews yet.