Air Receiver Inspections

An air receiver is a type of pressure vessel. It is a tank that stores compressed air for large demands in excess of compressor capacity.

A receiver should be selected so the design pressure is more than or equal to the maximum working pressure used throughout the workplace.

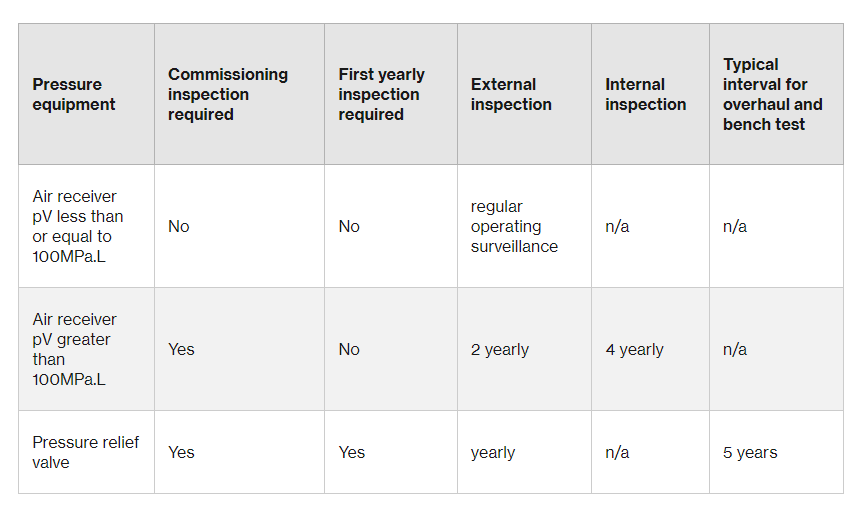

It is important to keep the air receiver in a safe working condition. Ensure inspections are done by a competent person in line with the following inspection intervals table.

You must keep a record of any inspection and maintenance carried out on pressure vessels with a hazard level A, B, C or D as determined by AS 4343 Pressure equipment.

Compressed air is used in a wide variety of manufacturing and commercial applications, and in some industries the quality of the air is extremely important

Problem

Inadequate inspection and maintenance of air receiver pressure vessels.

Inspection and maintenance often focuses solely on the compressor. The air receiver does not have moving parts and is not given the priority it requires.

Risks

Pressure vessels can fail and explode, causing injury and death. The Longford gas explosion in Victoria was the result of pressure vessel failure after a heat exchanger in the gas refining process exploded.

Controlling Risks

You must, so far as is reasonably practicable, eliminate or reduce any risk associated with plant.

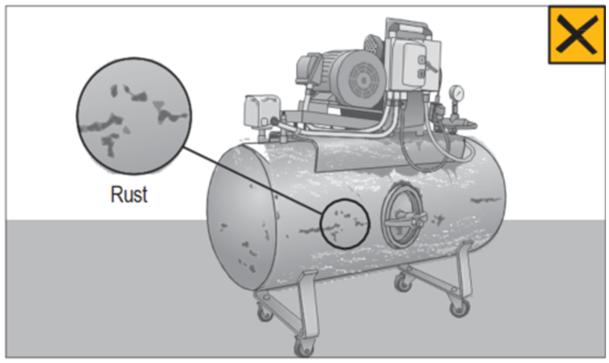

Figure 1: The poor external condition of this air receiver showing a build-up of rust, oil and dust, signals a need for improved operational surveillance, inspection and maintenance.

Safety Devices

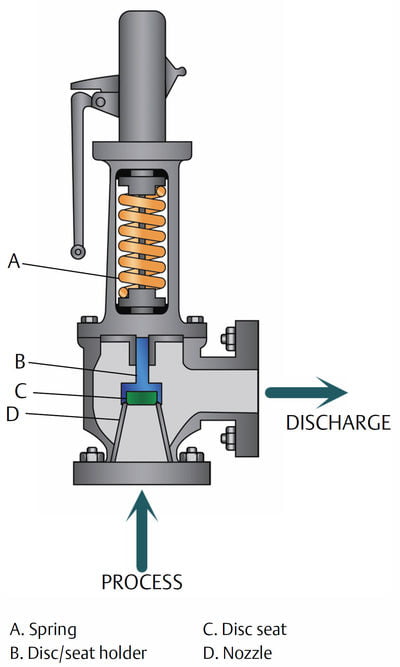

Ensure that the pressure relief valve is overhauled and bench tested by competent persons at intervals to keep it in a safe condition.

Operational surveillance and monitoring of the pressure relief valve, blowdown valve and pressure gauges should be built into standard operating procedures.

Other Components

Monitor, inspect and maintain according to the manufacturer or supplier’s recommendations, all components of the compressed air system, such as the air receiver, air compressor, air lines/hoses and fittings.

Inspection Intervals

Inspections should be carried out by competent person(s) at intervals to keep the air receiver in a safe condition.

Inspection intervals sourced from AS/NZS 3788:2006 Pressure equipment—In-service inspection.

Note: pV is determined by multiplying pressure (MPa) x volume (Litres).

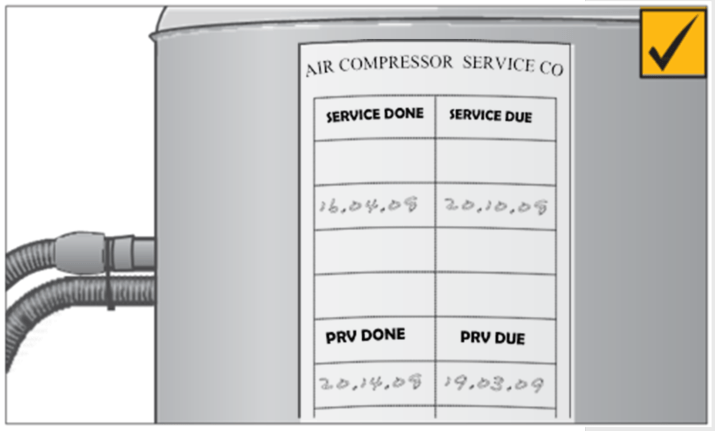

Figure 2: Inspection reminder sticker gives a quick visual reference on the status of the inspection program. This does not substitute for inspection records.